Surface Finishes for Multilayer PCBs and Their Impact (Business Opportunities - Marketing & Sales)

Hot-Web-Ads > Business Opportunities > Marketing & Sales

Item ID 16034264 in Category: Business Opportunities - Marketing & Sales

Surface Finishes for Multilayer PCBs and Their Impact | |

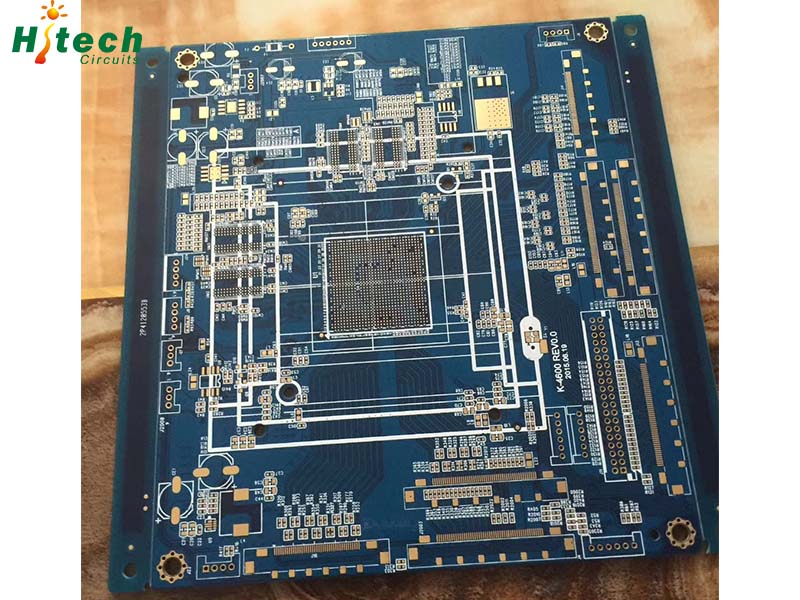

Multilayer PCBs are essential in modern electronic systems where high-density routing, signal integrity, and reliability are critical. While inner layers are encapsulated during lamination, the outer layers of a multilayer PCB are exposed for component assembly — making surface finish a key factor in performance and long-term reliability. Surface finish not only protects the exposed copper but also directly influences soldering quality, component compatibility, and board lifespan, especially in complex multilayer designs. Why Surface Finish Is Critical in Multilayer PCBs In a multilayer PCB, especially those with 6, 8, or more layers, outer-layer copper traces and pads are often extremely dense and designed for fine-pitch SMT components such as BGAs, QFNs, or high-pin-count connectors. A good surface finish must: Ensure consistent solderability across dense pad arrays Maintain flatness to support reliable assembly of micro-components Provide oxidation protection during storage and processing Be compatible with lead-free reflow profiles Handle multiple reflow cycles without degradation Multilayer PCBs often undergo more complex assembly and higher thermal stress, so the surface finish must meet higher standards than simple single- or double-layer boards. Common Surface Finishes for Multilayer PCBs 1. ENIG (Electroless Nickel Immersion Gold) The most popular surface finish for multilayer boards, especially in high-density and high-reliability applications. Provides excellent flatness for fine-pitch components (e.g. BGAs) Stable during multiple reflow cycles Compatible with high-speed signals due to smooth surface Long shelf life, ideal for staged assembly Slightly higher cost but justified by performance Widely used in servers, telecom equipment, and aerospace PCBs. 2. OSP (Organic Solderability Preservative) Preferred for cost-sensitive multilayer boards with fine-pitch components. Flat surface suitable for automated SMT Environmentally friendly and lead-free Lower cost than ENIG Limited shelf life, requires controlled handling Not ideal for boards requiring multiple assembly cycles Often used in consumer electronics and automotive applications. 3. Immersion Silver Used for multilayer boards requiring high signal integrity or RF performance. Low surface roughness ensures good impedance control Suitable for high-frequency multilayer PCBs Sensitive to tarnishing and handling Better electrical performance than ENIG in certain designs Good choice for communication equipment and high-speed digital boards. 4. Lead-Free HASL Sometimes used in low-cost multilayer boards, but not recommended for very dense designs. Cost-effective, robust finish Less flat surface can cause soldering issues on fine-pitch pads May lead to solder bridging in dense layouts Acceptable for through-hole or mixed technology boards Usually applied to industrial control or power-related multilayer PCBs. Surface Finish Considerations in Multilayer PCB Design When choosing a surface finish for multilayer PCBs, consider: Assembly method (SMT vs through-hole, single vs multiple reflows) Pad density and component type (especially fine-pitch packages) Signal performance needs (RF, impedance control, etc.) Environmental factors (RoHS, storage conditions) Budget vs reliability trade-offs In many high-reliability or mission-critical multilayer designs, ENIG or Immersion Silver is preferred despite higher cost, due to their consistent performance. Final Thoughts The outer layers of a multilayer PCB may seem like a small part of a complex system, but the choice of surface finish can make or break the final product. Whether it's ensuring reliable solder joints for 0.4 mm pitch BGAs, withstanding multiple reflow cycles, or maintaining performance in high-frequency circuits — the right surface finish is critical. Understanding the relationship between board complexity, material stack-up, and surface treatment is essential for delivering a reliable, high-performance multilayer PCB.  | |

| Target State: All States Target City : All Cities Last Update : May 22, 2025 2:52 AM Number of Views: 53 | Item Owner : Alisa Contact Email: Contact Phone: +86 18126460264 |

| Friendly reminder: Click here to read some tips. | |

Hot-Web-Ads > Business Opportunities > Marketing & Sales

© 2025 Hot-Web-Ads.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | USAOnlineClassifieds.com

2025-08-20 (0.223 sec)